-

Permanent Magnet Motor

-

Wind Turbines

-

Permanent Magnet Drive

-

Service Support

-

About Hiest

-

News

The two eminent contenders, Permanent Magnet Synchronous Motors (PMSM) and Asynchronous Motors stand ready for a showdown as we dissect their unique characteristics.

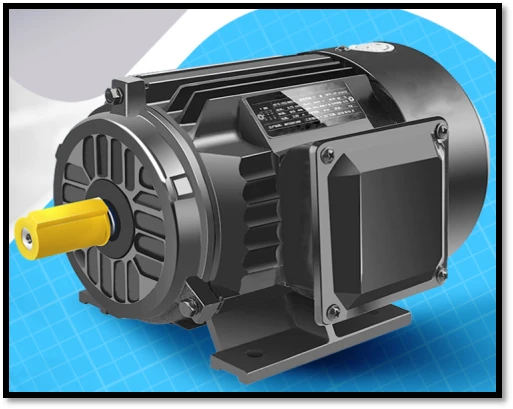

Asynchronous Motors: The Robust Workhorses

Known for their versatility and consistency, are used extensively in different household as well as industrial applications. The operational framework of these devices depends on the core principle of electromagnetic induction.

Operational Principle: Asynchronous motors work on the principle of electromagnetic induction. When exposed to alternating current (AC), the stator windings induce a rotating magnetic field. This magnetic field generates currents within the rotor, composed of conductive materials. The contact between the two magnetic fields leads to the rotation of the rotor.

Starting Torque: These motors are capable of providing significant starting torque, making them favorable for applications needing fast initiation, such as conveyors and water pumps.

Reliability: Known for their straightforward design and robustness, Asynchronous motors ensure ease of maintenance and affordability.

Speed Regulation: Asynchronous motors don’t require feedback devices for speed control. The rotational speed of an asynchronous motor essentially depends on the frequency of the supplied AC power. However, these motors show lower energy efficiency when operating at partial loads, which makes them less suitable for high-precision applications.

Permanent Magnet Synchronous Motors (PMSM): Precision and Efficiency

With ideals of precision, control, efficiency, and control, Permanent Magnet Synchronous Motors (PMSM) has prominence in various industries, including textile manufacturing, agriculture, industrial mixing, ventilation systems, and more.

Operating Principle: Featuring permanent magnets within the rotor, PMSMs have the operational advantage of establishing a static magnetic field. When exposed to alternating current (AC) within the stator windings, a rotating magnetic field is created. The permanent magnets in the rotor support this magnetic field to provide a synchronous and defined rotation.

Energy Efficiency: PMSMs are highly energy efficient, specifically under partial load conditions. This quality makes them a perfect choice for electric vehicles, where energy conservation prominently impacts range and performance.

Precise Control: Powered by advanced feedback systems and control algorithms, PMSMs display specific control over position and speed. This accuracy is important in robotics applications that need precision and consistency.

Compact Design: PMSMs have a compact, lightweight design that makes them suitable for applications with weight and space constraints. Moreover, their reduced heat generation eases the need for elaborate cooling mechanisms.

Cost: The cost of manufacturing Permanent Magnet Synchronous Motors is higher due to the assimilation of permanent magnets within the rotor. Moreover, they require dedicated feedback mechanisms and control systems to control operational overheads.

Decoding Motors: Choosing the Suitable Motor for Your Application

The selection between Permanent Magnet Synchronous Motors and Asynchronous Motors depends on the specific needs and nuances of the intended application. While asynchronous motors display robustness and flexibility, Permanent Magnet Synchronous Motors shine in energy efficiency, precision and higher torque. As we continue to progress technologically, the continuous development and enhancement of these motor technologies remain key to our developing industrial landscape.